Building Qatar’s Largest 3D-Printed Boat at GORD 3D Center

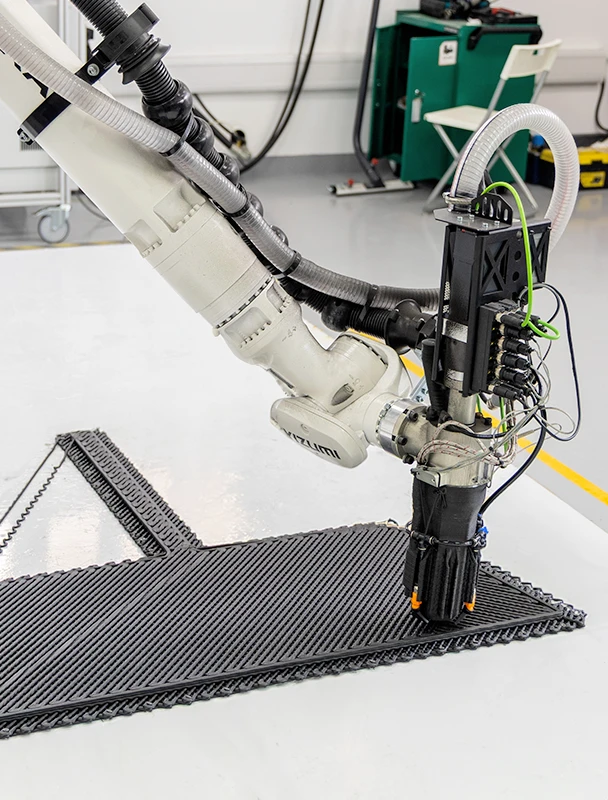

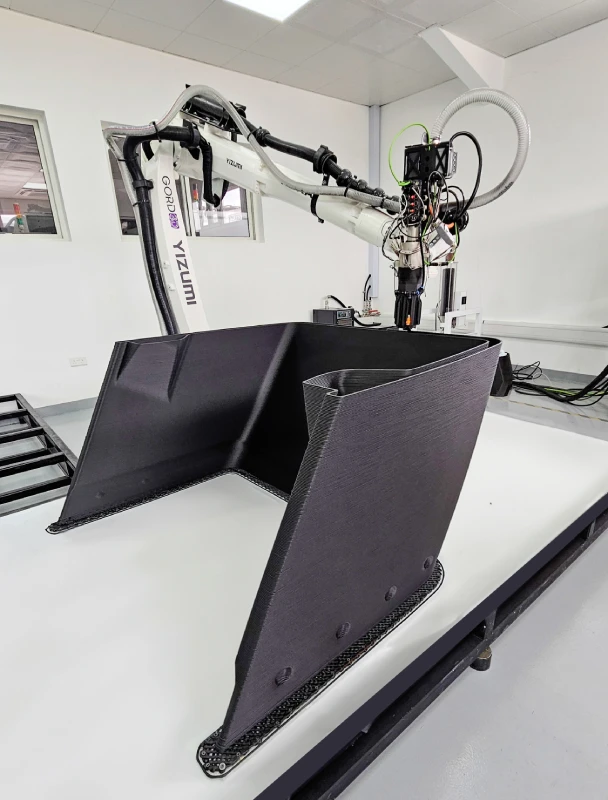

The largest 3D-printed boat in Qatar was created at GORD 3D Center, located in Qatar Science & Technology Park (QSTP). On April 24, 2025, after two weeks of high-tech printing, this 5-meter-long boat was finished using our advanced 3D printing process called Extrusion Deposition Modeling (EDM) with a robotic arm.

EDM works by slowly laying down melted material layer by layer to build strong, lightweight parts. We used a special polymer mixed with carbon fiber, called PPCF, to make the boat tough and durable enough for rough sea conditions.

At GORD 3D, everything starts with a detailed digital design that matches the client’s needs and is optimized for good performance on the water. Once the design is ready, our robotic arm moves smoothly and carefully to print the boat’s complex hull step by step.

This method allows us to create detailed shapes with very little wasted material, making the process more efficient than traditional boat building.

After printing, the boat parts are carefully finished and put together, turning the printed layers into a strong and seaworthy vessel. This smart and modern process cuts down production time and lets us make changes or improvements quickly.

GORD 3D is proud to lead the way in fast, flexible, and eco-friendly boat making using the latest 3D printing technology.