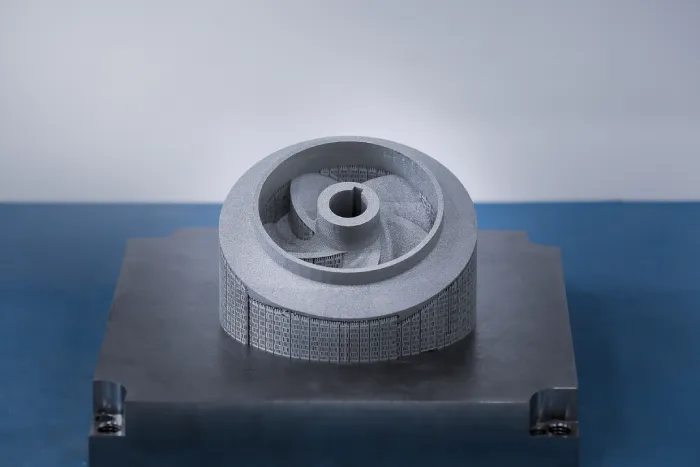

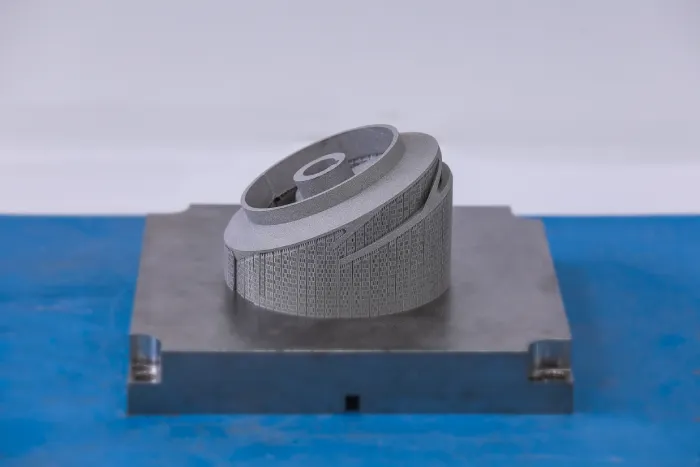

Exploring the Potential of Additive Manufacturing for Closed Impellers:

A Case Study by GORD 3D

Additive Manufacturing (AM), particularly Laser Powder Bed Fusion (LPBF), is increasingly recognized as a transformative technology for producing complex metal parts with high precision, minimal waste, and unprecedented design flexibility.

At GORD 3D, a leading 3D printing provider based in Qatar, our team recently investigated the feasibility of manufacturing closed impellers using LPBF with 316L stainless steel.

Why Closed Impellers Are Challenging to Manufacture

Impellers are critical rotating components used to transfer energy to fluids in pumps, turbines, and compressors. Depending on the application, impellers may be open, semi-open, closed, or screw-type.

Among these, closed impellers are the most challenging to manufacture due to their complex internal geometry, especially the integrated shroud, which encloses the blades.

Conventional manufacturing methods like casting and multi-stage welding struggle to fabricate closed impellers with acceptable precision and efficiency. These methods often result in:

- High material wastage

- Complex tooling and machining

- Dimensional variability and misalignment

- Significant energy consumption

Additive Manufacturing offers a layer-by-layer approach that eliminates the need for complex tooling, enabling the production of monolithic, intricate geometries such as enclosed impeller blades with minimal post-processing.

Study Objectives and Methodology

The aim of the study was to explore:

- Optimal build orientations

- The influence of energy distribution strategies

- Effects on surface finish and mechanical integrity

Using the E-Plus M260 LPBF system at GORD 3D’s facility in Qatar Science & Technology Park (QSTP), the team printed two impeller designs of 100 mm and 145 mm diameter in 316L stainless steel. Each design was fabricated at three build angles:

- 0° (horizontal)

- 30° (tilted)

- 90° (vertical)

The experimental matrix focused on analyzing:

- Surface roughness

- Internal fusion quality

- Microstructural variation

- Hardness and geometric stability

To mitigate down-skin defects common in steep overhangs, the team adjusted the down-skin energy density from 80% to 100% of the in-skin values to assess the impact on melt pool behavior and surface quality.

Key Findings

Optimal Build Orientation: 30°

- Offered the best balance between structural integrity, support requirement, and printability

- Reduced overhang-related defects and minimized recoater interference

- Resulted in improved surface finish and dimensional fidelity

Energy density Matters

- Increasing down-skin energy density to 100% of in-skin levels minimized surface defects like balling, incomplete fusion, and thermal distortion

- Enhanced interlayer bonding and reduced porosity in shrouded zones

Implications for Industry

- Demonstrated that closed impellers—previously difficult to produce—can now be manufactured monolithically using LPBF

- Opens the door for design optimization, mass customization, and localized manufacturing in critical sectors

This study validates LPBF as a viable solution for manufacturing complex rotating machinery components like closed impellers. The findings reveal that a 30° build angle, coupled with optimized energy density control, results in structurally sound, high-quality parts.

GORD 3D continues to push the frontier of advanced manufacturing in Qatar, offering industrial partners innovative solutions for complex design and production challenges.

Check out the full research on ResearchGate here.