Polymers and Composites Printing

Beyond prototypes, we print solutions!

Embrace the future of manufacturing with GORD 3D printing solutions tailored for industrial applications.

Contact us today to explore how our 3D Printing Industrial Services can advance your business.

Contact Information

- QSTP, Tech 1, Level 2 - Doha, Qatar

- 3d@gord.qa

- 4141 5000

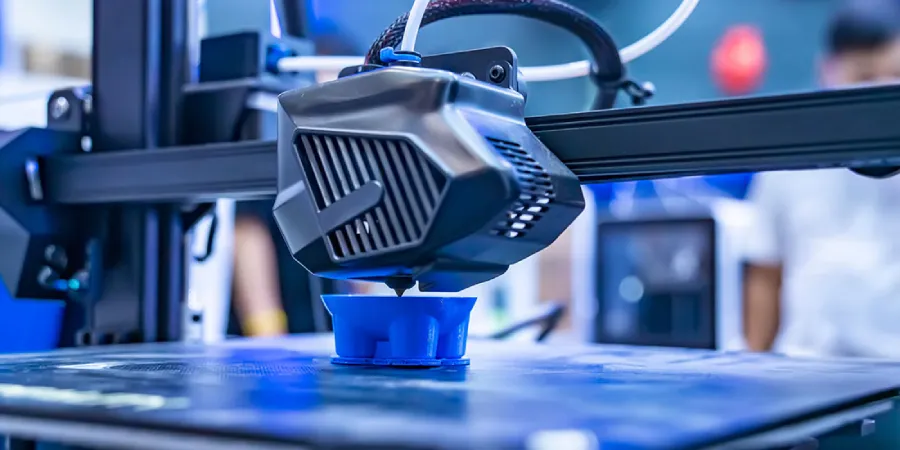

Polymers & Composites Printing

At GORD 3D, we specialize in advanced polymer 3D printing services. From Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) to Large-Scale Robotic 3D Printing and Composite 3D Printing, we’ve brought a full suite of cutting-edge technologies under one roof in Qatar — redefining the way you perceive polymer fabrication.

With FDM technology, we precisely stack layers of thermoplastic materials to produce durable, functional prototypes and end-use parts. Our SLS technology employs high-powered lasers to fuse powdered polymers into intricate forms, resulting in unparalleled geometrical intricacy and mechanical integrity.

With our Large-Scale Robotic 3D Printing capabilities, you can experience the future of polymer additive manufacturing where size knows no bounds. We turn your biggest visions into physical reality, whether they be architectural models, furniture, industrial components, or creative displays.

Dive into the realm of Composite 3D Printing, where we blend polymers with reinforcing materials like carbon fiber to produce lightweight, high-strength structures. This technology is used in oil and gas, aerospace, automotive, and other industries because it provides the ideal balance of strength and versatility.

Our expertise and varied variety of technologies ensure that your projects are imbued with innovation at every layer, from intricate prototypes to large-scale productions. Work with us to transform your polymer-based ideas into actual works of art and engineering excellence.

Frequently Asked Questions (FAQs)

What types of polymer and composite materials do you use in your 3D printing?

We offer a wide range of 3D printing materials, including high-performance polymers like PA6 CF, PA12 CF, Ultem 9085, PC, PP, TPU, and composites such as carbon fiber, fiberglass, Kevlar®, and Onyx. Our resin options include standard (white, black, clear), flexible, high-performance, casting, and color resins. Additional materials are available upon customer request.

Which polymer 3D printing technology is best suited for my product needs?

The best polymer 3D printing technology depends on your part’s application, not just the technology itself. We choose the right process and material based on your specific needs—such as strength, heat resistance, flexibility, or surface finish.

For example, in aerospace applications, Ultem 9085 is commonly used due to its flame retardancy and high strength-to-weight ratio. Once we understand your product requirements (e.g., mechanical stress, temperature, function), we can recommend the most suitable technology and material.

What is the maximum size and detail you can achieve with your polymer 3D printing at GORD 3D?

We can achieve high-resolution details with small layer thickness, depending on the selected material and printing technology. This allows us to produce parts with fine features, smooth surfaces, and precise dimensions tailored to your application.

Are the 3D printed polymer parts durable and suitable for functional use?

Yes, our 3D printed polymer parts are durable and suitable for functional use, especially with materials like PA12 CF, Ultem 9085, and carbon fiber composites. We select the best material and process to meet your part’s requirements.

How long does polymer 3D printing typically take, and what factors affect the cost?

Polymer 3D printing time varies from a few hours to several days, depending on part size, complexity, and layer thickness. Costs are influenced by material choice, print time, post-processing, and quantity. Larger or more detailed parts and high-performance materials generally increase both time and cost.

How does polymer 3D printing at GORD 3D support eco-friendly production goals for industries in Qatar?

GORD 3D supports eco-friendly production in Qatar by reducing material waste, enabling on-demand local manufacturing, and minimizing carbon emissions. This aligns with Qatar’s sustainability goals and promotes greener industrial practices.

What is required to print a part at GORD 3D Center?

To print a part at GORD 3D, you need to provide a 3D design file (STL, STEP, etc.), specify the desired material, share part details like size and tolerance, and approve the quotation and timeline. If needed, we can assist with design and material selection.

What can I do if I don’t have a CAD or STL file for 3D printing?

If you don’t have a CAD or STL file, we can help by creating the design for you through 3D scanning or modeling services. Just provide the physical part or your requirements, and our team will prepare the file needed for printing.